|

|

|

|

|

|

As always, if you have any comments about the newsletter or any of the information featured in this issue, we'd love to hear from you. Please

e-mail your feedback by clicking

here.

|

|

|

|

|

|

|

Tips on How to Save Set-Up Time

and Get More Jobs Done In Less Time

One of the big production bottlenecks for many shops is the time it

takes to set up the machine for the job. While set-up is a necessary

action for any job, there are some things one can do to reduce the

amount of time it takes, and thus get more jobs done in less time, and

cut delivery times.

If your machine is not cutting parts right now, you are not making money

right now!

How much time is spent on set-up time in your shop? For example, I went

and looked at a shop to review this specific point, and we found they

were typically spending from 4 hours to 1.5 days to set up a job – and

with short-run jobs that then only took a few hours to run the parts,

you can see how much saving set-up time would multiply into significant

improvements in number of parts cut and thus more

profitability!

One of the big time-absorbing tasks is setting up the tools for the job.

In many cases, there are a certain set of tools that could be used on

many jobs you run. By using the same group of standard tools, you can

leave them in the machine from job to job and thus save the time of

setting up those tools. Sure, each job might also need tools that are

not in the standard group, but every tool you don’t have to set up

(because it is left set up from job to job) saves you time. How many

tools could you standardize on and thus save time in this manner?

At first one might think this does not work because the ideal tool for

one job is rarely the same as the ideal tool for another job. However,

in many cases you could use a similar tool even if not perfectly ideal

-- the real question to calculate profitability is how much machining

time will you save by switching out tools versus the cost of setting up

the tools. In many cases, especially for short-runs, the savings by not

spending the set-up time far outweighs the number of seconds of

machine-time saved by using a slightly more optimum tool. At first one might think this does not work because the ideal tool for

one job is rarely the same as the ideal tool for another job. However,

in many cases you could use a similar tool even if not perfectly ideal

-- the real question to calculate profitability is how much machining

time will you save by switching out tools versus the cost of setting up

the tools. In many cases, especially for short-runs, the savings by not

spending the set-up time far outweighs the number of seconds of

machine-time saved by using a slightly more optimum tool.

Where do you start?

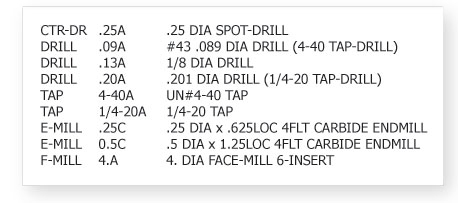

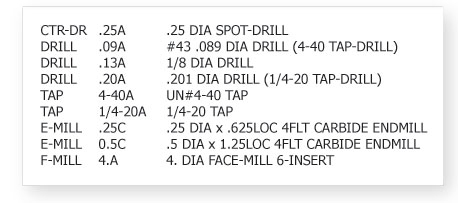

- Make a simple list of the tools you know could

be used on many jobs that come through your shop. For typical milling,

this could include for example a ¼- and ½-inch end-mill, a certain

spot-drill, certain taps and corresponding tap-drills, and maybe a few

drills that are used on a lot of parts.

- Now type that list up with an exact

specification – is it carbide or HSS? Is it 2-flute or 4? Is it stubby

length or long? etc.

- Now assign each of those standard tools a

standard name. On a Mazak mill, these would be called something like

“E-MILL .25A” – write that name on the list.

- Print that list out and give it to all the

programmers, set-up people and machinists working on these CNCs. See

if anyone has any further feedback, and get agreement that this is

going to be the standard list of tools that stay in each CNC all the

time.

- Post it by each programming station so it is

right at hand when making a program.

In the real world, often you will find the list is always expanding and no

one has the time to make the full complete list. But even just getting a

short list done will start saving time immediately. Don’t worry about

getting the list perfect, just get it started on the most common tools

used.

If you would like the computer to make your job even easier, here are a

few of the many ways that MazaCAM can help:

- MazaCAM has a function to print out the list

of tools used within a program. By using this function on a number

of your programs, you can start seeing what tools you use over and

over from job to job.

- Once you start standardizing tool-names, you

might find that old programs use other tool-names that should be

changed to your now standardized names. MazaCAM now makes this easy

with a function to replace a given tool-name to a different name

throughout the entire program with one command. (The feature can

even let you select from a Mazak’s Tool-Data, to make this even

easier.)

- MazaCAM offers a module that includes a way

for you to enter all your tools into a database, and thus help you

keep track of your tools, look them up and list them automatically

on tool-sheets/set-up sheets, etc.

Parting thought for the day:

In the real world, what determines value becomes the answer to the

ultimate questions:

-

“How much time and money will it

save me?” or

- “How much more time and money will

it make me?”, and

- “Does it work?”

Put ideas to test in the real world, not in the

world of competing ideas.

|

|

|

|

|

|

|

Now more than ever it is

important to work as efficiently as possible. You owe it to

yourself to find out what is available to help get parts made

faster with less effort and time.

News

Mazak Selects a Distribu-tor for the Western Re-gion

Resources

Visit the forum that is all about

Mazatrol.

TheMazatrolAdvantage.com

Tech Tip

Back-up your Mazak control data

Usually everything is fine, but once in a while, the Mazak control (like any electronic equipment) might hiccup, get hit by static-electricity, a voltage surge, or whatever, and lose all its data

>> Read More

|

|

|

Training

Drawing

Basic-Milling

Lathe

Chains and Layers

3D-Milling

C-Axis Lathe

|

MazaCAM programs the Integrex, e-Machine,

Nexus, Multiplex, Quick Turn and Super Quick Turn and the broad range of horizontal and vertical machining centers as well as all standard G-code CNCs.

- Mazatrol Edit

- Convert Between Controls

- Communications

- File Management

Great news for

Mazak users!

Performance Package

Show Tool Motion

Customized Tool-Sheet

-

Estimate

Run-Time

-

Tool Management

-

and much

more...

|

Need more information?

Call us for details:

408.249.1529 main

888.322.3226 toll-free

|

|

|

| |

|

|

|

|

|

|

At first one might think this does not work because the ideal tool for

one job is rarely the same as the ideal tool for another job. However,

in many cases you could use a similar tool even if not perfectly ideal

-- the real question to calculate profitability is how much machining

time will you save by switching out tools versus the cost of setting up

the tools. In many cases, especially for short-runs, the savings by not

spending the set-up time far outweighs the number of seconds of

machine-time saved by using a slightly more optimum tool.

At first one might think this does not work because the ideal tool for

one job is rarely the same as the ideal tool for another job. However,

in many cases you could use a similar tool even if not perfectly ideal

-- the real question to calculate profitability is how much machining

time will you save by switching out tools versus the cost of setting up

the tools. In many cases, especially for short-runs, the savings by not

spending the set-up time far outweighs the number of seconds of

machine-time saved by using a slightly more optimum tool.